Laser cutting has become the preferred method for making and designing leather across a variety of industries, allowing the creation of intricate patterns and detailed designs on a variety of leather products. As craftsmen, designers, and manufacturers delve into the realm of laser-cut leather, a number of questions may arise.

In this guide, we’ll provide specific steps for laser cutting leather, as well as answers to frequently asked questions related to laser cutting leather. Let’s dive into the world of precision craftsmanship and explore the many possibilities of laser cutting leather.

In this article:

Part 1: Can You Laser Cut Leather?

Yes, laser cutting is a common and effective method for cutting leather. Laser cutting machines use a focused laser beam to cut through the material with precision. This process is particularly suitable for intricate and detailed designs, allowing for clean and accurate cuts without the need for physical contact with the material.

When laser cutting leather, it's important to consider the type and thickness of the leather, as well as the power and speed settings of the laser cutter. Different leather types may require adjustments to the cutting parameters to achieve optimal results. Additionally, proper ventilation and extraction systems are typically used to remove any fumes or odors generated during the laser cutting process.

Overall, laser cutting provides a versatile and efficient way to cut leather for various applications, such as crafting, fashion, and manufacturing.

Part 2: What Types of Leather Can Be Laser Cut?

Laser cutting can be applied to various types of leather, but some types are more suitable than others. The effectiveness of laser cutting depends on factors such as the leather's thickness, tanning process, and overall composition. Here are some common types of leather that can be laser cut:

- Vegetable-tanned leather: This type of leather is often preferred for laser cutting due to its natural and firm characteristics. It's commonly used in crafts, accessories, and leather goods.

- Chrome-tanned leather: While not as ideal as vegetable-tanned leather, chrome-tanned leather can still be laser cut. However, it may produce more fumes during the cutting process.

- Full-grain leather: This is the top layer of the hide, and it maintains the natural grain pattern. Full-grain leather is often laser cut for high-end products and accessories.

- Top-grain leather: This is another high-quality option that retains the outer layer of the hide, providing a smooth and clean surface for laser cutting.

- Split leather: The inner layers of the hide are used for split leather, and it may not laser cut as cleanly as full-grain or top-grain leather. However, it can still be done with appropriate settings.

Part 3: How to Laser Cut Leather - Step by Step Guide

Laser cutting leather involves several steps to ensure a clean and precise result. Here's a step-by-step guide on how to laser cut leather:

Step 1. Choose the Laser Cutter:

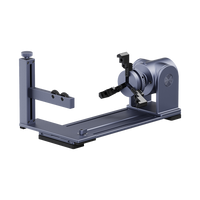

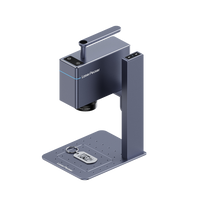

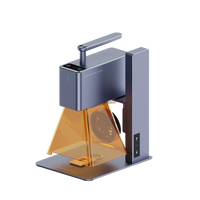

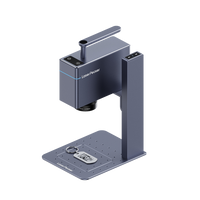

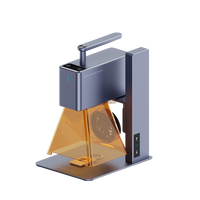

There are various types and models available suitable for leather cutting. If you want to laser cut leather at home, it's recommended to choose LaserPecker LX1 Foldable and Compact Laser Cutting Machine. You can easily laser cut leather with LaserPecker at home.

Step 2. Select Your Leather:

Choose the type of leather that suits your project. Consider factors such as thickness, color, and texture. Ensure that the leather is flat and properly prepared for cutting.

Step 3. Set Up the Laser Cutter:

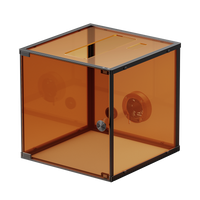

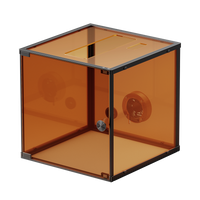

Ventilation: Make sure your laser cutting area is well-ventilated. Use the laser cutter in a space equipped with proper ventilation or an exhaust system to remove any fumes generated during cutting.

Focus the Laser: Adjust the laser cutter's focus to the thickness of your leather. This is crucial for achieving clean and precise cuts.

Step 4. Secure the Leather:

Place the leather on the laser cutter's bed and secure it in place. You can use masking tape or other non-permanent methods to keep the leather from moving during the cutting process.

Step 5. Prepare and Import the Design File:

Create or obtain a vector design file for the pattern you want to cut. Common file formats include SVG, DXF, or AI. Ensure that the design dimensions match the size of your leather piece.

Load your design file into the laser cutter's software. Arrange the design within the software to match the position of the leather on the cutting bed.

Step 6. Set Laser Parameters:

Configure the laser cutter settings based on the type and thickness of your leather. Consult the laser cutter's manual for recommended power, speed, and frequency settings.

Step 7. Test Cut:

Before cutting your actual design, perform a test cut on a small scrap piece of the same leather to ensure that the settings are correct. This helps prevent mistakes and ensures the desired outcome. Remember to protect your eyes with laser safety glasses.

Step 8. Start the Laser Cutting Process:

Once satisfied with the test cut, initiate the laser cutting process. Observe the machine and ensure that the cutting head follows the correct path. Be ready to pause or stop the process if needed.

Step 9. Remove the Cut Pieces:

After the laser cutting is complete, carefully remove the cut leather pieces from the cutting bed. Be gentle to avoid any damage to the delicate edges.

Step 10. Post-Processing:

Depending on your project, you may need to perform additional steps like cleaning the cut edges, applying finishes, or assembling the pieces into the final product.

Part 4: Applications of Laser Cut Leather

Laser cut leather finds applications in various industries and creative pursuits due to its precision and versatility. Here are some common applications of laser cut leather:

Fashion and Apparel:

Laser cutting is widely used in the fashion industry to create intricate patterns, designs, and details on leather garments and accessories such as jackets, shoes, bags, and belts.

Footwear:

Leather laser cutting is employed to craft detailed and precise patterns for shoe uppers and other components. It allows for intricate designs and customization in the production of leather shoes.

Accessories:

Leather accessories like wallets, purses, keychains, and watch straps often feature laser-cut details. The process enables the creation of complex and personalized designs on small leather items.

Home Décor:

Laser cut leather is used in home decor items such as lampshades, coasters, and wall art. The precision of laser cutting allows for intricate and decorative designs.

Automotive Interiors:

In the automotive industry, laser cut leather is utilized for crafting detailed and customized interiors, including seat covers, steering wheel covers, and other decorative elements.

Jewelry:

Leather jewelry pieces, including earrings, bracelets, and necklaces, can be intricately designed and cut using lasers. The precision enables the creation of delicate and complex patterns.

Crafts and DIY Projects:

Laser cut leather is popular among hobbyists and craft enthusiasts for creating personalized items such as bookmarks, coasters, and leather patches. The versatility of laser cutting allows for detailed designs even in small projects.

Prototyping and Product Development:

Designers and manufacturers use laser cutting to create prototypes and test designs before mass production. It allows for quick and precise iteration of product ideas.

Customization and Personalization:

Laser cutting enables the customization of leather goods with personalized designs, initials, or intricate patterns, making each item unique.

Art and Sculptures:

Artists use laser cut leather to create intricate pieces of art and sculptures. The precision of laser cutting allows for detailed and complex designs in leather artwork.

Labels and Tags:

Laser cutting is employed to create labels and tags for clothing and accessories. It provides a clean and professional look, especially for high-end or designer products.

Part 5: FAQs about Laser Cut Leather

1. Can all types of leather be laser cut?

Not all types of leather are equally suitable for laser cutting. Generally, vegetable-tanned, full-grain, and top-grain leathers work well. Chrome-tanned leather can be laser cut, but it may produce more fumes.

2. What thickness of leather can be laser cut?

The thickness of leather that can be laser cut depends on the specific laser cutter and its power. In general, laser cutters can handle leather with thicknesses ranging from 1mm to 6mm or more.

3. Can laser cutting damage the edges of the leather?

When done correctly, laser cutting provides clean and precise edges. However, improper settings or focusing can lead to charring or burning along the edges. Proper calibration and testing can help avoid damage.

4. Can I laser cut intricate patterns on leather?

Yes, laser cutting is ideal for intricate patterns and detailed designs on leather. The precision of the laser allows for the creation of complex and delicate patterns that may be challenging with other cutting methods.

5. Can laser cutting be used for mass production of leather goods?

Yes, laser cutting is commonly used in the mass production of leather goods, such as accessories, apparel, and automotive interiors. It allows for fast and precise cutting, contributing to efficient manufacturing processes.

6. Can I use laser-cut leather for functional items like wallets or bags?

Absolutely! Laser-cut leather is commonly used for functional items such as wallets, bags, and accessories. The precision of laser cutting ensures accurate assembly of pieces for durable and well-finished products.