Laser cutting technology has changed the way plastics are processed, providing a precise and versatile method for creating complex designs and functional parts.

This guide explores laser cut plastic, taking a look at the plastics suitable for laser cutting, the step-by-step process, its applications, and solving common questions about laser cutting plastics. Laser-cut plastics have found their way into every industry, from signage and prototyping to decorative arts and automotive parts, delivering unparalleled precision and efficiency.

In this article:

Part 1: 10 Best Plastics for Laser Cutting

When it comes to laser cutting plastics, certain materials are better suited for the process due to their properties and compatibility with laser technology. Here are 10 plastics that are commonly used and considered suitable for laser cutting:

- Acrylic (PMMA): Acrylic is a popular choice for laser cutting due to its transparency, ease of cutting, and ability to produce clean edges.

- Polycarbonate (PC): Polycarbonate is a durable and impact-resistant plastic that can be laser cut with good results. It is commonly used in applications requiring high strength.

- Polyethylene (PE): High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are both suitable for laser cutting. HDPE is often used for its rigidity, while LDPE is more flexible.

- Polypropylene (PP): Polypropylene is another thermoplastic that can be laser cut effectively. It is known for its chemical resistance and lightweight properties.

- Polyvinyl Chloride (PVC): PVC is a versatile plastic that can be laser cut, but it's important to note that the process may release chlorine gas, so adequate ventilation is necessary.

- Polyester (PET): PET is a strong and transparent plastic that can be laser cut. It is commonly used in packaging materials and other applications.

- Polyoxymethylene (POM): Also known as Delrin, POM is a high-performance engineering plastic suitable for laser cutting. It has excellent dimensional stability.

- Polyethylene Terephthalate Glycol-Modified (PETG): PETG is a clear plastic with good impact resistance. It is often used as a substitute for acrylic in some applications.

- Polyurethane (PU): Polyurethane can be laser cut, and it is known for its flexibility and abrasion resistance. It is commonly used in the production of gaskets and seals.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a thermoplastic known for its strength and impact resistance. It can be laser cut, but proper ventilation is important.

Part 2: How to Laser Cut Plastic - Step by Step Guide

Laser cutting plastic involves using a focused laser beam to cut through the material, and it is a precise and efficient method. Here's a step-by-step guide on how to laser cut plastic:

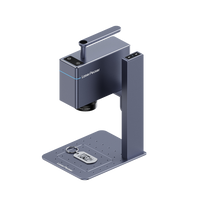

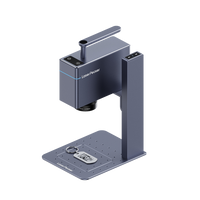

Step 1. Prepare the Laser Cutting Machine:

Make sure the laser cutting machine is equipped with a laser suitable for cutting plastic materials.

Step 2. Choose the Right Plastic Material:

Select a plastic material that is suitable for laser cutting. Materials such as acrylic, polycarbonate, polyethylene, and others mentioned in the previous part are commonly used.

Step 3. Set Up the Artwork:

Create or import the design you want to cut into a vector graphics software. Ensure that the file is formatted correctly, with the right dimensions and cut lines.

Step 4. Configure Laser Cutting Parameters:

Adjust the focus of the laser beam according to the thickness of the plastic. Consult the manufacturer's guidelines for the specific plastic material you are using. Set up the laser cutting parameters, including power, speed, and frequency, based on the material and its thickness. Test the settings on a scrap piece if needed.

Step 5. Secure the Plastic Material:

Secure the plastic sheet on the laser cutting bed using clamps or a vacuum table to prevent movement during the cutting process. Ensure that the material lies flat and is free from any warping.

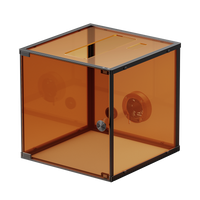

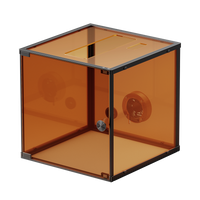

Step 6. Ventilation and Safety Measures:

Ensure proper ventilation in the workspace, especially when cutting materials like PVC that may release harmful fumes. Use a laser cutting machine equipped with a fume extraction system, and wear appropriate personal protective equipment (PPE), such as laser safety glasses.

Step 7. Focus the Laser:

Adjust the laser focus to the correct distance from the material surface. This ensures that the laser beam is concentrated for optimal cutting performance.

Step 8. Run a Test Cut:

Before cutting the entire design, run a test cut on a small section of the material to verify that the laser settings are correct. Adjust as needed.

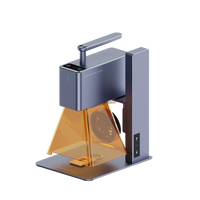

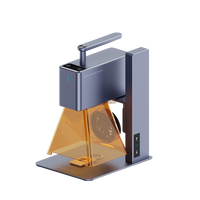

Step 9. Start the Laser Cutting Process:

Load the prepared design file into the laser cutting software. Double-check the positioning of the design on the material. Start the laser cutting process, and monitor it closely.

Step 10. Post-Cutting Inspection:

Once the cutting is complete, inspect the cut edges for smoothness and quality. Remove the cut pieces from the laser cutting bed.

Step 11. Clean and Maintain the Machine:

Clean the laser cutting machine and its components regularly to ensure optimal performance. Follow the manufacturer's guidelines for maintenance.

Part 3: Applications of Laser Cut Plastic

Laser-cut plastic finds applications in various industries due to its precision, versatility, and ability to create intricate designs. Here are some common applications of laser-cut plastic:

1. Signage and Displays:

Laser-cut plastic is widely used in the creation of signage and displays for businesses, events, and retail environments. Acrylic, in particular, is a popular choice for laser-cut signs because it can be cut into intricate shapes and letters with precise edges. The transparency of acrylic also allows for the incorporation of backlighting, enhancing the visual impact of the signage.

2. Prototyping and Model Making:

Laser-cut plastic is frequently used in prototyping and model making across various industries, including product design and architecture. Engineers and designers use laser cutting to create precise prototypes of parts, components, or entire products from materials like acrylic or ABS. This allows for quick iteration and testing before finalizing a design for mass production.

3. Custom Packaging and Enclosures:

Laser cutting is employed in the production of custom packaging and enclosures for electronics, consumer goods, and industrial equipment. Plastics like PET, PETG, and ABS can be laser cut to create precise shapes and designs that match the specific dimensions and requirements of the product. Laser-cut plastic packaging can enhance the aesthetics of a product while providing a protective and functional enclosure.

4. Art and Decorative Applications:

Laser-cut plastic is often used in artistic and decorative applications. Artists and designers leverage the precision of laser cutting to create intricate patterns, sculptures, and decorative elements. Whether it's a piece of wall art, jewelry, or intricate home decor items, laser-cut plastic allows for the realization of intricate and detailed designs that might be challenging to achieve with other methods.

5. Automotive Components:

In the automotive industry, laser-cut plastic is used for creating various components, including interior panels, gaskets, and trim pieces. The precision of laser cutting ensures that components fit together accurately, and the ability to cut complex shapes allows for innovative designs in automotive aesthetics and functionality.

Part 4: FAQs about Laser Cut Plastic

1. Can laser-cut plastic be recycled?

In many cases, laser-cut plastic scraps can be recycled. However, the recyclability depends on the type of plastic used and local recycling facilities. It's recommended to segregate laser-cut plastic waste by type and check with local recycling guidelines.

2. Can laser cutting produce sharp corners and fine details in plastic?

Yes, laser cutting is capable of producing sharp corners and fine details in plastic due to its high precision. However, the achievable level of detail may depend on factors such as the type of plastic, its thickness, and the laser cutting machine's capabilities.

3. Can laser cutting be used for creating 3D shapes in plastic?

Laser cutting is primarily a 2D cutting process, but multiple 2D layers can be stacked or assembled to create 3D structures. For more intricate 3D shapes, additional processes like laser engraving or CNC machining may be combined with laser cutting.

4. Is laser-cut plastic suitable for food contact applications?

Certain plastics, such as food-grade acrylic or PETG, are suitable for food contact applications. However, it's essential to verify the material's compliance with food safety regulations and ensure that the laser cutting process and any additional treatments are food-safe.