Laser engraving on silver involves using a concentrated beam of light to etch or engrave designs, patterns, or text onto silver surfaces. This process holds significant importance in various industries, including jewelry making, customization, and personalization of items.

This comprehensive guide aims to provide a step-by-step guide to engrave silver. It covers essential aspects such as preparation, techniques, troubleshooting, and advanced tips to help both beginners and experienced artisans achieve remarkable results.

In this article:

Part 1: Understanding Laser Engraving on Silver

Laser engraving utilizes a focused laser beam to remove material from the silver's surface, creating a permanent mark. The beam's intensity, speed, and focus determine the depth and clarity of the engraving.

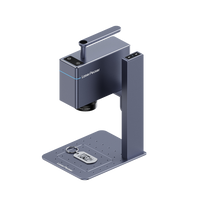

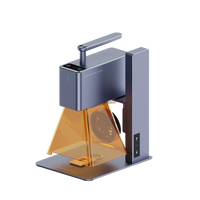

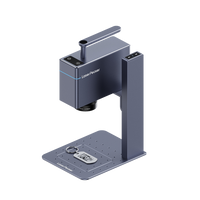

Different types of lasers, such as fiber, CO2, or diode lasers, have varying capabilities in engraving silver. Understanding the strengths and limitations of each type is crucial for achieving desired results.

The reflective nature and thermal conductivity of silver pose challenges during engraving, influencing settings and techniques required for successful outcomes. Understanding these characteristics is vital for effective engraving.

Part 2: Preparing Silver for Engraving

1. Surface Preparation and Cleaning Techniques

Cleaning the silver surface thoroughly before engraving is essential to remove any oils, residues, or impurities that could hinder the engraving process. Methods like alcohol wipes or specialized cleaners ensure a pristine surface for optimal results.

2. Choosing Suitable Designs for Engraving

Selecting the right design is crucial for successful engraving. Factors such as size, complexity, and compatibility with the silver surface need consideration. Design software or online resources can aid in creating or choosing appropriate designs.

3. Software and Design Considerations for Optimal Results

Using design software compatible with the engraving machine is key. Understanding file formats, resolution, and image editing can help optimize designs for engraving on silver, ensuring clarity and precision in the final product.

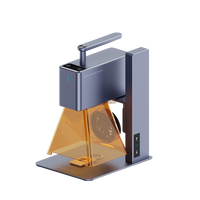

Part 3: Setting Up Laser Engraving Machine

1. Calibration and Focusing the Laser

Calibration: Ensuring the laser engraving machine is properly calibrated is crucial. This involves aligning the laser beam's path to achieve accurate positioning on the silver surface.

Focusing: Fine-tuning the focal point of the laser beam is essential for achieving the desired engraving depth and clarity. Adjust the focus based on the thickness of the silver.

2. Adjusting Settings for Different Types of Engraving

Power and Speed Settings: Experiment with power and speed settings to find the optimal combination for various engraving depths and designs. Test different settings on sample pieces before proceeding with the final engraving.

Resolution and DPI: Higher resolutions and dots per inch (DPI) settings often result in finer details but may take longer to engrave. Strike a balance between resolution and engraving speed.

3. Testing the Engraving on a Sample Piece

Before engraving the final piece, always conduct test runs on a similar silver sample. This allows adjustments to be made to settings and ensures the desired outcome before proceeding with the actual engraving.

Part 4: Techniques for Laser Engraving on Silver

1. Surface Engraving vs. Deep Engraving: Differences and Applications

Surface Engraving: Light engraving on the surface creates markings without penetrating deeply. Ideal for intricate designs and personalization on jewelry and decorative items.

Deep Engraving: Penetrating the silver's surface to create deeper markings. Suitable for larger objects or when a more pronounced effect is desired.

2. Tips for Achieving High-Quality Engraving

Optimal Speed and Power: Find the right balance between laser power and speed to avoid excessive heat buildup while ensuring adequate material removal.

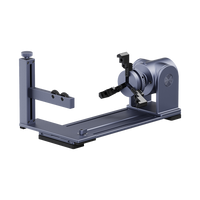

Material Support and Positioning: Use supports or fixtures to secure the silver piece in place during engraving to prevent movement or vibration that could affect precision.

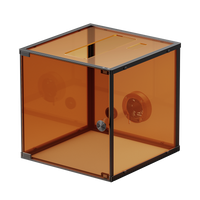

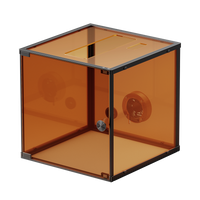

Managing Heat and Reflections: Implement strategies to manage heat buildup and reflections from the silver's surface, such as using cooling systems or adjusting the angle of the engraving.

Part 5: Troubleshooting Common Issues

1. Common Engraving Errors

Incomplete Engraving: If the engraving appears incomplete or faded, it could be due to insufficient power or speed settings. Adjust the parameters to ensure proper material removal without compromising quality.

Blurred or Uneven Engraving: Check for issues with focus or alignment. Ensure the laser is properly focused and aligned perpendicular to the silver surface for uniform engraving.

Burn Marks or Overheating: Excessive heat can cause burn marks on the silver. Reduce power settings or increase engraving speed to mitigate heat buildup without compromising the engraving quality.

2. Dealing with Inconsistencies in Engraving Depth or Clarity

Surface Variation: Uneven surfaces may result in inconsistent engraving depth. Consider leveling the surface or adjusting settings to accommodate surface irregularities.

Material Impurities: Contaminants or impurities on the silver's surface can affect engraving quality. Thoroughly clean the surface before engraving to prevent inconsistencies.

3. Maintenance Tips for the Laser Engraving Machine

Regular Cleaning and Maintenance: Keep the laser engraving machine clean, especially the lenses and mirrors, to ensure optimal performance. Follow manufacturer-recommended maintenance schedules.

Calibration Check: Periodically check and recalibrate the machine to maintain accuracy and precision in the engraving process.

Replacing Consumables: Replace worn-out or degraded components such as laser tubes, lenses, or filters to maintain consistent engraving quality.

Part 6: Hot FAQs About Engraving Silver

Q1. How to Engrave Silver by Hand?

Engraving silver by hand involves using handheld tools like gravers, burins, or hand engraving tools to etch designs onto the silver surface. It requires skill, patience, and precision to create intricate and detailed engravings.

Q2. How to Engrave Silver at Home?

Engraving silver at home can be done using various methods. Laser engraving machines or rotary tools equipped with appropriate engraving bits can be used for detailed and precise engravings. Always ensure proper safety measures and follow guidelines when working with tools at home.

Q3. How to Engrave Silver with a Dremel?

Engraving silver with a Dremel involves using a rotary tool with suitable engraving bits or attachments. Secure the silver piece firmly and use the Dremel at a slow speed to etch designs onto the silver surface. Practice on scrap pieces first to get a feel for the tool's speed and pressure needed for desired results.

Conclusion

In conclusion, mastering laser engraving on silver is an art that combines technical expertise with creative vision. It's about harnessing the power of technology while respecting the subtleties of a precious material. This guide serves as a compass, offering guidance, tips, and insights to steer through the intricacies of the process.

May this guide be a companion on your path toward mastering the art of laser engraving on silver, transforming your creations into timeless pieces of beauty and craftsmanship.