Engraving, an age-old craft that has adorned historical artifacts, religious objects, and cherished possessions for centuries, stands as a testament to human creativity and artistry. Among the myriad materials used for this craft, brass holds a distinctive allure due to its versatility and durability.

Brass, an alloy of copper and zinc, offers a unique canvas for engravers. In this guide, we delve into the captivating world of engraving brass-a journey that combines tradition, skill, and innovation.

In this article:

Part 1: What is Brass?

Brass is a metal alloy made primarily of copper and zinc, although other elements may also be added in smaller quantities to achieve specific properties. It's valued for its durability, malleability, corrosion resistance, and attractive golden-like appearance. The proportions of copper and zinc in the alloy determine its characteristics, such as color, hardness, and workability.

The typical composition of brass includes approximately 60-70% copper and 30-40% zinc, but variations exist depending on the desired properties. This alloy can also contain trace amounts of other metals like lead, tin, aluminum, or nickel to enhance certain features or modify its behavior during machining.

Due to its versatility and range of qualities, brass finds applications in various industries and crafts. Its malleability allows it to be formed into intricate shapes, making it a popular choice for decorative items, musical instruments (such as trumpets and cymbals), hardware (locks, doorknobs), plumbing fixtures, electrical components, and more.

Brass also has an inherent antimicrobial property that makes it useful in applications where hygiene is crucial, like doorknobs, bathroom fixtures, and healthcare equipment.

Part 2: How to Laser Engrave Brass?

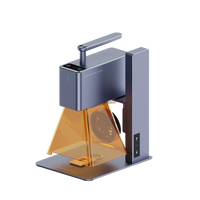

Laser engraving is a precise and efficient method for engraving on various materials, including brass. Here's a step-by-step guide on how to laser engrave brass:

Materials and Tools Needed:

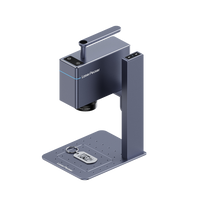

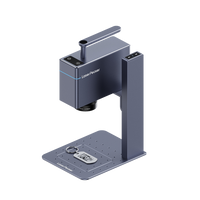

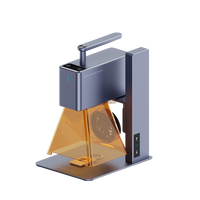

- Laser Engraving Machine: metal laser engraving machines are commonly used for engraving on brass.

- Brass Sheet or Object: Ensure it is clean and free from any coatings or residues.

- Computer Design Software: Software that's compatible with your laser engraving machine for creating or importing the design.

Steps to Laser Engrave Brass:

Step 1. Prepare the Design:

Using design software, create or import the desired design for engraving. Ensure the dimensions and positioning align with the brass object's size and shape.

Step 2. Set Up the Laser Engraving Machine:

Turn on the laser engraving machine and ensure it's properly calibrated.

Place the brass sheet or object securely within the engraving area and adjust the focus of the laser head to the surface of the brass.

Step 3. Configure Laser Engraving Settings:

Set the laser parameters based on the specifics of the brass material and the desired depth or intensity of the engraving. This includes adjusting power, speed, and frequency settings.

It's advisable to conduct test engravings on scrap pieces of brass to fine-tune the settings before engraving the final piece.

Step 4. Load the Design and Start Engraving:

Upload the design file to the engraving software connected to the laser machine.

Double-check the alignment and positioning of the design on the brass surface within the software interface.

Start the engraving process, ensuring that the machine operates smoothly and consistently. Monitor the process to ensure the design is engraved accurately.

Step 5. Post-Engraving Clean-Up:

Once the engraving is complete, remove the brass object from the machine.

Clean the engraved area using a mild detergent or alcohol to remove any residue or debris resulting from the engraving process.

Optionally, polish the engraved area for a more refined finish, using appropriate brass cleaners or polishing compounds.

Safety Precautions:

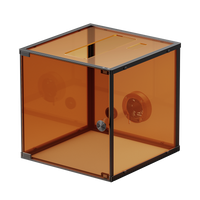

- Protective Gear: Wear appropriate safety glasses and follow all safety guidelines recommended for operating the laser engraving machine.

- Ventilation: Ensure proper ventilation in the workspace, especially when engraving metals, to remove any fumes or particles generated during the process.

Part 3: Are There Other Ways to Engrave Brass?

Yes, there are several traditional and modern methods to engrave brass apart from laser engraving. Here are some of the common techniques used:

- Hand Engraving: This traditional method involves using specialized hand tools like gravers or burins to cut or carve designs into the brass surface. Skilled artisans manipulate these tools to create intricate patterns, texts, or images. Hand engraving requires precision, patience, and expertise.

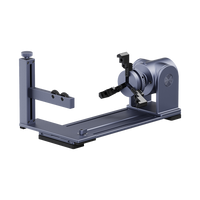

- Rotary Engraving: Using a rotary engraving machine equipped with rotating cutting tools, this method cuts into the brass surface to create engravings. The machine's spinning cutter, guided by computerized or manual controls, etches designs onto the brass with high precision.

- Pantograph Engraving: Pantograph machines employ a system of linked arms and styluses to transfer a design from a template to the brass surface. As the operator moves the stylus over the template, the machine duplicates the movement onto the brass, engraving the desired pattern.

- Chemical Etching: This process involves applying an acid or chemical solution onto a brass surface covered with a stencil or resist material. The solution selectively etches the exposed areas, creating engraved designs. Chemical etching allows for detailed and intricate patterns but requires careful handling of hazardous chemicals.

- Electrochemical Etching:Similar to chemical etching, electrochemical etching uses an electrical current along with an electrolyte solution to etch designs onto the brass surface. A stencil or mask is applied to protect areas not meant for engraving while the electrical process selectively etches the exposed areas.

- Stamping or Embossing: Stamping or embossing uses pressure to imprint designs onto the brass surface using specialized stamps or dies. The raised or depressed patterns created through this method can achieve various decorative effects.

Part 4: FAQs About Brass Engraving

- What is brass engraving?

Brass engraving is the process of etching or cutting designs, patterns, or text onto brass surfaces using various techniques, including hand tools, machines, or chemical processes.

- What tools are commonly used for brass engraving?

Tools for brass engraving include hand gravers, burins, rotary engraving machines, laser engraving machines, pantograph machines, chemical etching solutions, and specialized stamps or dies.

- Can any brass surface be engraved?

Yes, most brass surfaces can be engraved. However, the quality of engraving might vary based on the alloy composition, surface finish, and hardness of the brass. It's advisable to test engraving on a small area or scrap piece before working on the final object.

- What are the applications of engraved brass?

Engraved brass finds applications in various fields, including jewelry making, decorative items, signage, trophies, plaques, instrument detailing (musical instruments), industrial components, personalization of objects, and artistic crafts.

- How durable are engraved brass designs?

Engraved brass designs are generally durable and long-lasting. The depth and quality of the engraving, along with proper finishing and protective coatings, contribute to its longevity. However, engraved surfaces can wear over time with extensive use or exposure to harsh conditions.

- Is it possible to engrave detailed designs on brass?

Yes, brass is a favorable material for intricate designs due to its malleability. Techniques like hand engraving or laser engraving can achieve detailed and precise engravings on brass surfaces.

- How can I maintain engraved brass pieces?

Regular cleaning with a mild detergent or brass cleaner can help maintain the appearance of engraved brass. Avoid abrasive cleaners that might scratch the engraved surface. Applying a protective coating or lacquer can also preserve the engraving.

- Can I engrave brass at home?

Yes, with the right tools and techniques, it's possible to engrave brass at home. Hand engraving can be learned with practice, and there are smaller laser engraving machines available for personal use. However, for complex or large-scale projects, professional engraving services might be preferred.

Conclusion

Brass engraving is an art form that melds tradition with modern techniques, offering a versatile canvas for intricate designs. Whether using hand tools or cutting-edge machines, the process yields enduring beauty on brass surfaces.

Throughout this guide, we've explored diverse methods, tools, and applications. Embrace the artistry of brass engraving, whether you're a beginner or a seasoned craftsman. Experiment, practice, and let your creativity shape timeless engravings on brass.