Silicone, a versatile material known for its flexibility and durability, has found its way into various industries and products. Engraving on silicone opens up opportunities for customization and personalization. In this blog, we'll explore how to engrave silicone, and the tools needed to effectively engrave on silicone surfaces.

![]()

In this article:

Part 1: What is Silicone?

Silicone is a synthetic polymer made of silicon, oxygen, carbon, and hydrogen. Its unique properties include heat resistance, flexibility, non-reactivity, and biocompatibility, making it suitable for diverse applications. From kitchenware and medical devices to electronics and fashion, silicone's versatility shines through its use in seals, adhesives, cookware, and more.

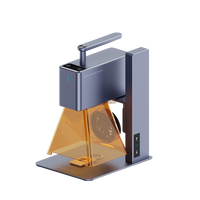

Part 2: How to Laser Engrave Silicone?

Tools Needed:

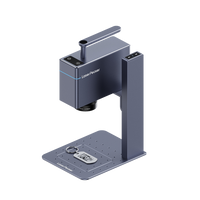

- Laser engraving machine for Silicone

- Silicone material

- Computer design software

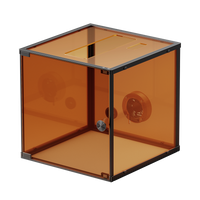

- Safety goggles and protective gear

Detailed Steps for Laser Engraving Silicone:

- Prepare the Design: Create or select the design to be engraved using compatible design software.

- Prepare the Silicone: Place the silicone material securely within the laser engraving machine.

- Set Parameters: Adjust the laser settings based on the silicone type and desired engraving depth.

- Test Engrave: Before engraving the final design, conduct a test on a small area to ensure settings are correct.

- Begin Engraving:Start the engraving process, ensuring the machine accurately follows the design.

- Inspect and Clean: After engraving, carefully inspect the result and clean off any debris or residue.

Tips for Laser Engraving Silicone:

- Always wear appropriate protective gear when operating the laser engraving machine.

- Test on a small area before engraving the entire design to avoid errors.

- Use high-quality silicone for better engraving results.

Part 3: How to Engrave Silicone Watch Band?

Engraving a silicone watch band can be a fantastic way to personalize your accessory. Here's a guide on how to engrave a silicone watch band:

Tools Needed:

- Laser engraving machine (preferred) or specialized hand engraving tools

- Silicone watch band

- Computer with design software (if using a laser engraving machine)

- Safety goggles and protective gear

Steps to Engrave a Silicone Watch Band:

- Select the Design: Decide on the design or text you want to engrave on the silicone watch band. This could be a name, a special date, a symbol, or any other desired motif.

- Laser Engraving Method:

- Create or import your chosen design into the laser engraving machine software.

- Securely place the silicone watch band within the machine, ensuring it's flat and stable.

- Adjust the settings on the laser engraving machine according to the type of silicone and the desired depth of engraving.

- Perform a test run on a small area to ensure the settings are appropriate before proceeding to engrave the entire design onto the watch band.

- Initiate the engraving process, allowing the machine to precisely etch the chosen design onto the silicone surface.

- Inspect and Clean: Once the engraving process is complete, carefully inspect the engraved area to ensure the design has been accurately transferred. Use a soft cloth to clean off any debris or residue from the watch band.

- Test the Band: Before wearing the watch, ensure that the engraving has not compromised the integrity or functionality of the band. Check for any rough edges or alterations that might affect comfort or the band's ability to secure the watch to your wrist.

- Post-Engraving Care: Keep the watch band clean and dry after engraving to maintain the quality of the engraving over time.

Tips:

- Prioritize safety by wearing protective gear, especially when using a laser engraving machine.

- Test the engraving on a small, inconspicuous area of the watch band first to ensure the desired results.

- Choose an appropriate design size and depth that won't compromise the structural integrity of the watch band.

Part 4: Are There Other Ways to Engrave Silicone?

Besides laser engraving, other methods to engrave on silicone include:

- Hand Engraving: Using specialized tools to manually engrave designs onto the silicone.

- Chemical Etching: Applying specific chemicals to etch designs onto the silicone.

- Pad Printing: Using a silicone pad to transfer ink onto the silicone surface.

Part 5: FAQs About Silicone Engraving

1. Can all types of silicone undergo laser engraving?

Not every silicone variant is suitable for laser engraving. It's recommended to conduct a test on a small area before proceeding.

2. Is it safe to laser engrave food-grade silicone?

Yes, laser engraving is generally safe for food-grade silicone as long as the process doesn't introduce contaminants.

3. Is it possible to color silicone after engraving?

Yes, silicone can be colored using specialized dyes or paints post-engraving.

4. Does engraving affect the flexibility of silicone?

If done correctly, engraving should minimally impact the flexibility of silicone.

5. Can laser engraving be performed on curved silicone surfaces?

Yes, with appropriate equipment and settings, laser engraving can be executed on curved surfaces.

6. Are all types of silicone compatible with chemical etching?

Certain chemicals may react differently with silicone, so it's essential to proceed cautiously and test on a small area first.

7. Does hand engraving provide precise results on silicone?

Hand engraving demands skill but can yield intricate and precise designs on silicone.

8. Will pad printing fade over time on silicone?

While quality ink and proper application can ensure durability, fading may occur gradually over time with pad printing on silicone surfaces.

Conclusion

Engraving on silicone offers a myriad of opportunities for customization across various industries. Whether through laser engraving, pad printing, chemical etching, or hand engraving, understanding the methods and choosing the right approach can lead to impressive and personalized results on silicone surfaces. Always prioritize safety measures and test your methods before executing the final engraving to achieve the best outcomes.