Titanium, known for its durability and resistance to corrosion, is a versatile metal used in various industries, from aerospace engineering to jewelry making. Engraving titanium requires precision and the right tools, especially due to its toughness. In this blog, we'll delve into the methods and techniques for engraving titanium effectively.

Engraving titanium offers a personalized touch to jewelry, medical implants, and industrial components. Whether it's for identification, decoration, or branding purposes, mastering the art of engraving titanium can unlock numerous creative possibilities.

In this article:

Part 1: What is Titanium?

Titanium, a lustrous transition metal, possesses exceptional strength-to-weight ratio, making it ideal for aerospace, medical implants, automotive components, and sports equipment. Its resistance to corrosion and biocompatibility also make it a favorite in the medical field for implants and prosthetics.

Part 2: How to Laser Engrave Titanium?

Tools Needed:

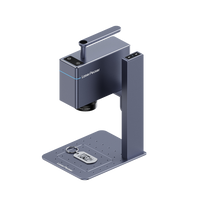

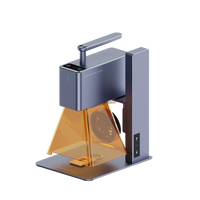

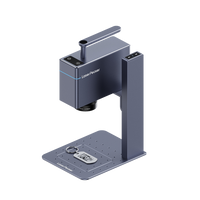

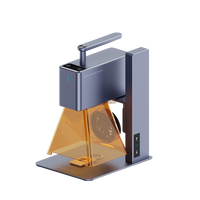

- Laser engraving machine specifically designed for metal engraving

- Computer with compatible design software

- Titanium surface to engrave

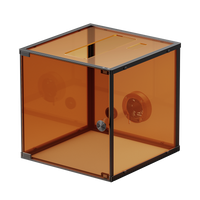

- Personal protective equipment (safety glasses, gloves)

Steps for Laser Engraving Titanium:

- Surface Preparation: Clean the titanium surface thoroughly to remove any dirt, oil, or debris.

- Design Creation: Using specialized design software, create or upload the desired engraving pattern or text.

- Settings Adjustment: Configure the laser engraving machine settings such as power, speed, and resolution according to the titanium's properties.

- Test Run: Before engraving on the actual titanium surface, perform a test run on a small piece to ensure the settings are accurate.

- Engraving: Secure the titanium piece firmly in place and initiate the engraving process, ensuring precise alignment and focus.

- Quality Check: After engraving, inspect the design for clarity and depth. Make adjustments if necessary.

Tips for Laser Engraving Titanium:

- Use higher power settings but slower speeds for deeper and clearer engravings.

- Experiment with different engraving depths and settings on scrap pieces to determine the optimal parameters.

- Regularly clean the engraving area and lens of the laser machine for better results.

Part 3: Are There Other Ways to Engrave Titanium?

- Diamond Drag Engraving:

Diamond-tipped tools scratch the surface of the titanium to create an engraved design. It's a slower process but yields precise results.

- Chemical Etching:

This method involves using chemicals to create an etched design on the titanium surface. A stencil or mask protects the areas you don't want etched.

- Electrochemical Etching:

Utilizing electricity and an electrolyte solution, this method etches designs onto the titanium surface using a stencil and a power supply.

Part 4: FAQs About Titanium Engraving

Q1. Is titanium easy to engrave?

Titanium is a tough metal, making it more challenging to engrave compared to softer metals like aluminum. However, with the right tools and techniques, precise engraving is achievable.

Q2. Can any laser engraving machine engrave titanium?

Not all laser engraving machines are suitable for engraving titanium. Ensure you have a machine specifically designed for metal engraving.

Q3. Can I engrave titanium jewelry at home?

Yes, with the proper equipment and precautions, you can engrave titanium jewelry at home using a suitable laser engraving machine.

Q4. Does engraving titanium weaken its structure?

When done correctly, surface engraving typically doesn't affect the structural integrity of titanium.

Q5. Can titanium be engraved by hand?

Hand engraving titanium is possible but requires specialized tools and considerable skill due to its hardness.

Q6. Is titanium safe for laser engraving?

Laser engraving titanium is safe, but ensure proper ventilation and use protective gear due to potential fumes.

Q7. Can you color titanium after engraving?

Anodizing is a method that can be used to add color to engraved titanium surfaces.

Q8. How deep can you engrave titanium?

The depth of engraving can vary but typically ranges from a few microns to several millimeters, depending on the laser settings and desired outcome.

Conclusion

Engraving titanium requires specialized techniques and tools due to its toughness and durability. Whether using laser engraving, chemical etching, or other methods, understanding the material properties and employing precision is key to achieving high-quality and lasting engravings on titanium surfaces. Experimentation, proper preparation, and attention to detail will lead to stunning and durable results in titanium engraving projects.