Copper engraving stands as a venerable art form, weaving its way through history, leaving an indelible mark on various industries and artistic endeavors. From the intricate designs etched onto copper plates to the stunning prints and decorative pieces, this age-old technique continues to captivate artisans and creators with its timeless appeal.

In this comprehensive guide, we embark on a journey to unravel the intricacies of copper engraving. From understanding the fundamentals to mastering the techniques, we delve deep into the art form's nuances, equipping enthusiasts and beginners with the knowledge needed to explore and excel in this craft.

In this article:

Part 1: What is Copper?

Copper is a chemical element with the symbol 'Cu' and atomic number 29 on the periodic table. It is a ductile, malleable, and versatile metal known for its excellent thermal and electrical conductivity. With a distinct reddish-orange hue, copper has been utilized by humans for thousands of years due to its various beneficial properties.

Key Characteristics of Copper:

- Malleability and Ductility: Copper is highly malleable and ductile, allowing it to be easily shaped and formed into various structures, wires, and intricate designs.

- Conductivity: It is an exceptional conductor of electricity and heat, making it invaluable in electrical wiring, electronics, and heat exchangers.

- Corrosion Resistance: Copper exhibits good resistance to corrosion, particularly in atmospheric conditions, developing a protective patina over time.

- Antimicrobial Properties: Copper possesses natural antimicrobial properties, making it useful in various applications where inhibiting the growth of bacteria is essential.

Uses of Copper:

- Electrical Wiring: Copper is extensively used in electrical wiring, power generation, and transmission due to its high conductivity.

- Construction and Architecture: It's employed in roofing, gutters, architectural details, and piping due to its durability and resistance to corrosion.

- Industrial Applications: Copper is crucial in various industries, including automotive, aerospace, and manufacturing, where its thermal conductivity and corrosion resistance are highly valued.

- Art and Decoration: Copper's aesthetic appeal and malleability make it popular in artwork, sculptures, jewelry, and decorative pieces.

- Healthcare: Copper's antimicrobial properties have led to its use in healthcare settings for surfaces and materials to reduce the spread of infections.

Part 2: How to Laser Engrave Copper?

Laser engraving on copper can yield precise and intricate designs, offering a clean and detailed finish. Here's a general guide on how to laser engrave copper:

Materials and Equipment Needed:

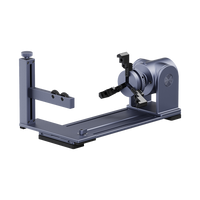

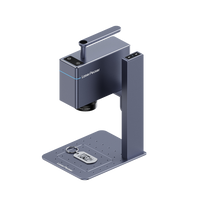

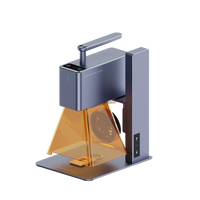

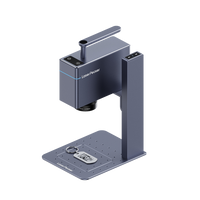

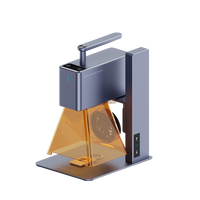

- Laser Engraving Machine: Ensure the laser engraver is suitable for metal engraving and has sufficient power to engrave copper.

- Copper Sheet or Object: Use copper sheets or objects specifically designed for laser engraving to achieve optimal results.

- Design Software: Prepare or create the design or pattern you want to engrave using software compatible with the laser engraving machine.

- Safety Gear: Wear appropriate safety gear, including goggles and gloves, when operating the laser engraving machine.

Steps for Laser Engraving on Copper:

Step 1. Preparation:

Ensure the copper surface is clean and free from any oils, dust, or residues. Use a suitable cleaning agent to wipe the surface before engraving.

Step 2. Set Up the Engraving Machine:

Power on the laser engraving machine and adjust the settings according to the manufacturer's guidelines and the specifics of copper engraving. Parameters such as power, speed, and frequency might need adjustments.

Step 3. Design Preparation:

Import or create the design in the engraving software. Adjust the dimensions, position, and orientation of the design as needed.

Step 4. Testing and Calibration:

Perform a test run on a small area of the copper sheet to ensure the settings are appropriate and the engraving depth and quality meet your expectations. Adjust settings if necessary based on the test.

Step 5. Engraving Process:

Place the copper sheet or object in the laser engraving machine's designated area, ensuring it's securely fixed to prevent movement during the engraving process.

Start the engraving process as per the settings defined in the software. The laser will trace the design onto the copper surface, removing material to create the engraved pattern or text.

Step 6. Inspection and Finishing:

Once the engraving is complete, carefully remove the engraved copper sheet from the machine.

Inspect the engraved area for quality and completeness. Sometimes, the engraved design might require cleaning to remove any residual debris or markings left during the engraving process.

Step 7. Optional Finishing Touches:

Depending on the desired appearance, you can apply certain finishes or coatings to the engraved copper surface. This might include polishing, applying patina for an aged look, or sealing the engraved area.

Safety Precautions:

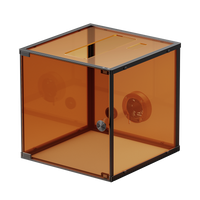

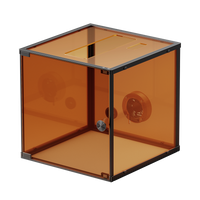

- Eye Protection: Always wear appropriate goggles to shield your eyes from the laser.

- Ventilation: Ensure proper ventilation in the workspace to remove any fumes or gases generated during engraving.

- Follow Manufacturer Guidelines: Adhere strictly to the manufacturer's instructions and safety guidelines for the specific laser engraving machine being used.

Part 3: Are There Other Ways to Engrave Copper?

Yes, there are several traditional and modern methods to engrave copper aside from laser engraving. These methods vary in technique, tools used, and the effects they produce. Some common alternatives to laser engraving copper include:

Traditional Hand Engraving:

- Graver or Burin Engraving:

Technique: Using specialized hand tools called burins or gravers to cut into the copper surface, creating lines, patterns, and textures.

Detail: Allows for precise control over line thickness, depth, and direction, enabling intricate and detailed designs.

- Etching:

Technique: Applying an acid-resistant substance (such as wax or a special resist material) to protect certain areas of the copper while exposing the rest to an acid bath.

Effect: The acid bites into the exposed areas, creating an etched design or pattern on the copper surface.

Variation: There's a variation called intaglio printing, where the etched design is inked and used for printmaking.

Modern Methods:

- Electrochemical Etching:

Technique: Using an electric current and an electrolyte solution, this method involves selectively etching the copper surface through a stencil or mask placed on the material.

Control: Offers precise control over the depth and intricacy of the engraved design.

- Chemical Etching:

Technique: Similar to traditional etching but involves using chemicals rather than acid to selectively etch the copper surface.

Control: Allows for controlled etching of the copper by varying the chemical solution and duration of exposure.

- Diamond Drag Engraving:

Technique: Utilizing a tool with a diamond tip to physically scratch or drag across the copper surface, creating engraved lines or patterns.

Precision: Provides high precision and durability for creating detailed designs on copper.

Rotary Engraving:

Technique: Involves the use of a rotary engraving machine equipped with cutting tools to engrave the copper surface.

Applications: Ideal for creating both shallow and deep engravings on various copper objects and materials.

Part 4: FAQs About Copper Engraving

- What is copper engraving?

Copper engraving is a technique of incising or carving designs, patterns, or text onto a copper surface using various tools or methods, such as hand tools, etching processes, or modern technologies like laser engraving.

- What tools are commonly used for hand engraving on copper?

Hand engraving on copper typically involves specialized tools like burins, gravers, or diamond-tipped tools to carve or incise the metal surface to create intricate designs or patterns.

- How is copper traditionally etched for engraving?

Traditional etching involves covering the copper surface with an acid-resistant substance, exposing specific areas for etching, and then immersing the copper plate into an acid solution. The acid bites into the exposed areas, creating the engraved design.

- Can copper be laser engraved?

Yes, copper can be laser engraved using specialized laser engraving machines designed for metal engraving. Laser engraving on copper allows for precise and detailed designs by removing material from the surface through controlled laser energy.

- What are the applications of engraved copper?

Engraved copper finds applications in various fields such as printmaking, jewelry making, decorative arts, industrial markings, and personalized items due to its aesthetic appeal and durability.

- How can I protect an engraved copper surface?

Protective coatings like lacquer, wax, or clear sealants can be applied to safeguard the engraved copper surface from oxidation, tarnishing, or damage. Regular cleaning and gentle handling also help maintain the engraved copper's appearance.

- What is the difference between engraving and etching on copper?

Engraving involves physically cutting or incising the copper surface using tools, while etching involves selectively corroding the metal surface through chemical or acid exposure to create the desired design.

- Is copper engraving suitable for beginners?

Copper engraving techniques vary in complexity, but some methods, such as simple hand engraving or electrochemical etching, can be learned by beginners with practice and guidance.

- Can I create prints from engraved copper plates?

Yes, engraved copper plates are commonly used in printmaking, such as intaglio printing. Ink is applied to the engraved surface, wiped off the raised areas, and then transferred to paper through a printing press, resulting in a printed image.

- Where can I learn more about copper engraving techniques?

Various resources, including online tutorials, workshops, books, and art institutions, offer guidance and learning opportunities for individuals interested in exploring copper engraving techniques and methods.

Conclusion

In conclusion, the art of engraving copper stands as a timeless craft that marries precision, creativity, and the unique properties of this versatile metal. Whether through traditional hand techniques involving burins and etching tools or modern methods like laser engraving, the allure of copper engraving lies in its ability to transform a simple sheet of metal into a canvas of intricate designs, patterns, and text.

The artistry and skill involved in copper engraving echo the rich history and traditions of craftsmanship while embracing modern technologies for innovation. Through dedication, practice, and a passion for the craft, individuals can delve into this fascinating realm, carving their mark on copper and leaving an indelible legacy in this celebrated art form.