Gold has always been revered for its timeless beauty and value. Engraving on gold items adds an extra layer of personalization, turning these precious pieces into cherished heirlooms. Whether it's a custom message on a wedding band or an intricate design on a pendant, the art of gold engraving holds a special place in the world of craftsmanship.

In this comprehensive guide, we will delve into how to engrave gold, exploring the techniques, tools, and steps required to master this art form. From understanding the basics to mastering the finer details, this step-by-step guide aims to equip you with the knowledge and skills needed to engrave gold like a seasoned artisan.

In this article:

Part 1: What Types of Gold Are Suitable for Engraving?

- 24-Karat Gold (24K)

Purity: 99.9% gold content.

Softness: Highly malleable but less suitable for intricate engravings due to its softness.

- 18-Karat Gold (18K)

Composition: 75% gold, 25% other metal alloys.

Strength: More durable than 24K gold, suitable for detailed engravings.

- 14-Karat Gold (14K)

Composition: 58.3% gold, 41.7% other alloys.

Durability: Considerably durable, ideal for precise engravings.

- Gold Alloys and Variations

White Gold: Mix of gold and white metals.

Rose Gold: Gold alloy with copper for a pinkish hue.

Colored Gold Variations: Achieved by mixing gold with specific metals to produce different hues.

Part 2: How to Laser Engrave Gold?

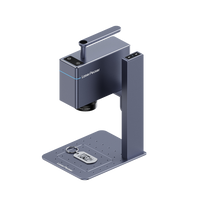

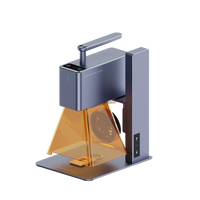

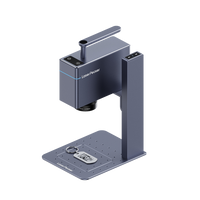

Step 1. Prepare the Laser Engraving Machine

Select the Right Machine: Ensure you have access to a laser engraving machine designed to work with metals like gold.

Set Parameters: Adjust the laser settings such as power, speed, and frequency based on the type and thickness of the gold.

Step 2. Prepare the Gold Surface

Clean the Surface: Ensure the gold surface is clean and free from any dust, oils, or residues that could affect the engraving quality.

Secure the Gold: Use clamps or a jig to firmly hold the gold piece in place to prevent movement during engraving.

Step 3. Design Preparation

Create or Import Design: Use design software to create the desired engraving pattern or import an existing design.

Scale and Position: Scale the design to fit the gold surface and position it accurately using the software.

Step 4. Test Engraving

Test on a Sample Piece: Before engraving on the actual gold piece, perform a test engraving on a similar material or a small section of the gold to ensure the settings and design are as desired.

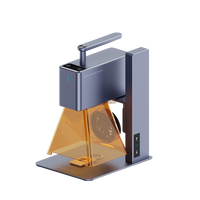

Step 5. Laser Engraving Process

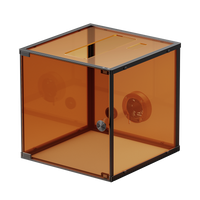

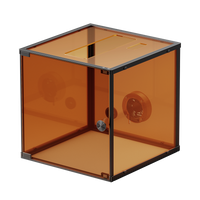

Safety Precautions: Put on protective eyewear and follow safety guidelines while operating the laser machine.

Start Engraving: Initiate the laser engraving process. The laser beam will remove material from the gold's surface according to the specified design and settings.

Monitor Progress: Keep an eye on the engraving process to ensure precision and quality.

Step 6. Post-Engraving Steps

Inspect the Engraving: After the engraving is complete, carefully inspect the design to ensure it meets your expectations.

Clean the Engraved Area: Use a soft brush or cloth to remove any debris or residues from the engraved area.

Step 7. Final Touches

Optional Finishing: Depending on the desired finish, consider polishing the engraved area for a more refined look.

Quality Check: Conduct a final inspection to ensure the engraving is clean and precise.

Tips for Laser Engraving Gold

- Use High-Quality Images or Designs: Detailed and high-resolution designs yield better engraving results.

- Adjust Settings Carefully: Fine-tune laser settings to achieve the desired depth and quality without damaging the gold.

- Practice on Similar Materials:If possible, practice engraving on similar metals before working on precious gold items to gain confidence and proficiency.

Part 3: Are There Other Ways to Engrave Gold?

1. Hand Engraving

- Description: Hand engraving is a traditional technique involving the use of handheld tools to carve designs directly onto the gold surface.

- Tools Used: Gravers, burins, and various hand tools with different shaped tips for cutting and shaping.

- Technique: Engravers use these tools to manually carve designs, patterns, or texts onto the gold surface with precision and artistry.

- Advantages: Offers a high level of artistic expression and customization, allowing for intricate and personalized designs.

- Challenges: Requires significant skill, practice, and hand-eye coordination to achieve precise and detailed engravings.

2. Machine Engraving

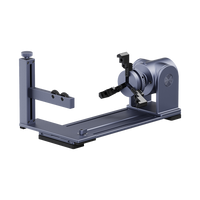

- Description: Utilizes specialized machines equipped with rotary or diamond-tipped tools to engrave designs onto gold.

- Types of Machines: Engraving machines can range from simple rotary tools to computerized systems controlled by software.

- Process: Designs are either manually traced or digitally inputted into the machine, which then engraves the pattern onto the gold surface.

- Advantages: Offers precision, consistency, and the ability to replicate designs accurately.

- Challenges: Limited flexibility for intricate handcrafted designs compared to hand engraving.

3. Chemical Etching

- Description: Involves using chemicals to etch or corrode the gold surface, creating designs or patterns.

- Process: A resist material, such as wax or a specialized film, is applied to protect the areas that should remain unetched. The exposed areas are then treated with chemicals to create the desired design.

- Advantages: Allows for intricate and detailed designs, especially for fine lines and delicate patterns.

- Challenges: Requires careful handling of chemicals and meticulous application to achieve precise results.

4. Impact or Hammer Engraving

- Description: Involves using specialized tools like hammers and punches to create indentations or impressions on the gold surface.

- Technique: Artisans use controlled strikes with punches or chisels to create patterns or texts through the force of impact.

- Advantages: Ideal for creating textured surfaces or bold, deep engravings.

- Challenges: Requires skill and control to ensure uniformity and precision in the depth and placement of the impressions.

5. Electrochemical Etching

- Description: Uses an electric current and specialized electrolytes to etch designs onto the gold surface.

- Process: A stencil or mask is placed on the gold, and an electric current is passed through the electrolyte, etching the exposed areas.

- Advantages: Enables precise and controlled etching without physical contact with the gold surface.

- Challenges: Requires expertise in handling electrical equipment and electrolytes safely.

Part 4: Frequently Asked Questions (FAQs) About Gold Engraving

Q1. Is it possible to engrave on any type of gold jewelry?

Yes, most types of gold jewelry can be engraved. However, the suitability for engraving may vary based on factors such as the karat of gold, its hardness, and the intricacy of the design desired. Higher karat gold (e.g., 18K or 14K) is often preferred for detailed engravings due to its durability.

Q2. Can previously engraved gold jewelry be re-engraved?

Yes, in most cases, previously engraved gold jewelry can be re-engraved. However, this depends on the depth and nature of the existing engraving. Deeper or heavily engraved pieces may require additional preparation or refinishing before a new engraving can be added.

Q3. How deep does the engraving go into the gold surface?

The depth of the engraving typically varies based on the engraving method and the design's requirements. In general, engravings can range from surface-level etchings to deeper cuts, but for most jewelry, shallow engravings are preferred to avoid compromising the structural integrity of the piece.

Q4. Can gold-plated jewelry be engraved?

Gold-plated jewelry usually has a thin layer of gold applied to another metal base. While it's possible to engrave on gold-plated surfaces, the depth and durability of the engraving might be limited due to the thin gold layer. Engraving too deeply could expose the base metal beneath the plating.

Q5. How much does it cost to get gold jewelry engraved?

The cost of gold engraving varies based on factors like the complexity of the design, the method used, and the jeweler or engraver's rates. Simple text engravings might cost less than intricate designs or custom patterns. It's best to inquire with jewelers or engraving specialists for specific pricing.

Q6. Can gemstones be engraved along with the gold setting?

Gemstones are typically not engraved directly due to their hardness and potential for damage. Engraving the metal setting around the gemstones is possible, but caution is necessary to avoid impacting the stones during the engraving process.

Q7. How do I care for engraved gold jewelry?

To maintain the beauty of engraved gold jewelry, clean it regularly using mild soap and warm water. Avoid harsh chemicals or abrasive materials that could damage the engraving. Periodic professional cleaning and inspection by a jeweler can also help preserve the engraving's quality.

Q8. Can I personalize my own gold jewelry with engraving?

Yes, many jewelers or specialized engravers offer custom engraving services. You can personalize gold jewelry with names, dates, special messages, or unique designs to add sentimental value and make it a cherished keepsake.

Conclusion

Gold engraving stands as a testament to the union of craftsmanship and personalization, transforming precious gold pieces into cherished works of art. Whether through the precision of laser engraving, the artistry of hand engraving, or other innovative methods, the beauty of gold becomes a canvas for meaningful expressions and intricate designs.

May your engraved gold pieces not only shine with elegance but also resonate with the stories and emotions they hold, creating heirlooms to be cherished for generations to come.