Stainless steel engraving involves etching or marking designs, text, or patterns onto stainless steel surfaces. This process is widely used for various applications, including personalized items, industrial marking, and artistic creations. The durability and resistance to corrosion of stainless steel make it an ideal material for engraving.

In this blog, we will provide a comprehensive guide on how to engrave stainless steel, covering applications of stainless steel engraving, tools needed, techniques, and tips for successful engraving.

In this article:

Part 1: Applications of Stainless Steel Engraving

- Industrial Identification and Marking: Stainless steel engraving serves as a crucial method for industrial identification, marking parts, components, and equipment. Its resilience to harsh conditions makes it an ideal choice for serial numbers, labels, and specifications in various industries, including aerospace, manufacturing, and machinery.

- Personalization and Customization: The versatility of stainless steel engraving allows for personalized items and customization. From jewelry and trophies to gifts and mementos, stainless steel engraving adds a touch of uniqueness and permanence, making it a popular choice for creating personalized keepsakes.

- Artistic and Decorative Applications: Artists and designers often leverage stainless steel engraving for creative expression. Its ability to hold intricate designs and patterns makes it suitable for sculptures, architectural elements, and artworks. Whether used in public art installations or private collections, stainless steel engraving offers durability and aesthetic appeal.

- Medical and Instrumentation Use: Stainless steel's hygienic properties make it a preferred material in medical equipment and instrumentation. Engraving on surgical tools, equipment identification, and medical devices benefit from stainless steel's durability and corrosion resistance, ensuring longevity and clear identification.

- Commercial Signage and Branding:Businesses utilize stainless steel engraving for signage, branding, and displays. Its professional appearance, durability, and ability to withstand outdoor conditions make it a popular choice for company logos, plaques, and informational signage in commercial settings.

Stainless steel engraving's versatility across various industries and its ability to withstand environmental challenges while retaining its aesthetic appeal make it a sought-after method for a wide array of applications.

Part 2: Preparation for Stainless Steel Engraving

Gathering Necessary Materials and Tools

- Stainless Steel Blanks or Items: Choose the stainless steel items or blanks to be engraved, ensuring they are compatible with the chosen engraving method.

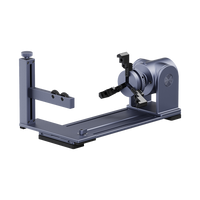

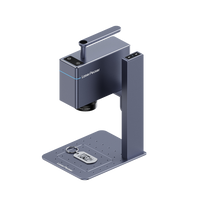

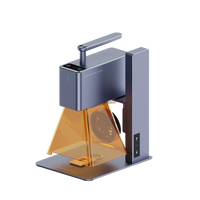

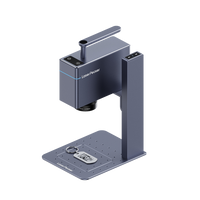

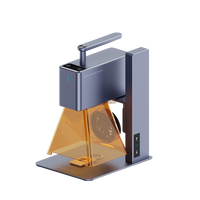

- Engraving Machine or Tools: Select the appropriate engraving machine or tools required for the specific technique (laser, rotary, or chemical etching).

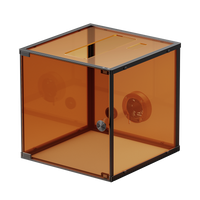

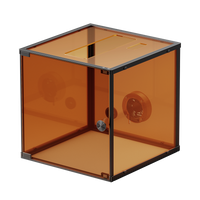

- Safety Equipment: Essential safety gear such as gloves, goggles, and protective clothing to ensure personal safety during the engraving process.

Cleaning the Stainless Steel Surface

- Removing Debris and Contaminants: Thoroughly clean the stainless steel surface, removing any dust, grease, or residues that may affect the engraving process.

- Using Appropriate Cleaning Agents: Utilize suitable cleaning agents or solvents to ensure the surface is completely free from contaminants, allowing for optimal engraving results.

Part 3: How to Laser Engrave Stainless Steel?

Can I Laser Engrave Stainless Steel?

Laser engraving on stainless steel is indeed possible and widely practiced. The process involves using high-powered lasers to etch or mark designs, text, or patterns onto the surface of stainless steel items. However, achieving successful results requires appropriate laser power, techniques, and surface preparation due to stainless steel's composition and reflective properties.

What Kind of Laser Can Engrave Stainless Steel?

- Fiber Lasers: High precision, efficient lasers ideal for directly marking stainless steel surfaces.

- High-Power CO2 Lasers: Specialized CO2 lasers (above 100 watts) can mark stainless steel using specific coatings or additives.

- Nd:YAG Lasers: Emit high-energy pulses for precise engraving on stainless steel and other metals.

- Fiber-CO2 Hybrid Lasers: Combine features of both fiber and CO2 lasers for versatile material engraving.

- Pulsed Fiber Lasers: Deliver intense, short pulses of energy for detailed stainless steel engraving.

- UV Lasers:Capable of producing fine markings on some stainless steel surfaces with high resolution.

- Green Lasers: Create contrast on certain stainless steel surfaces through oxidation or chemical reaction for marking.

How to Laser Engrave Stainless Steel? Step-by-step Guide

Step 1: Preparation

Choose a high-quality stainless steel item or surface for engraving.

Clean the surface thoroughly to remove any dirt, oil, or contaminants that might affect the engraving process.

Step 2: Setting Up the Laser Engraving Machine

Ensure the laser engraving machine is equipped with the appropriate settings and power for engraving stainless steel.

Test the laser settings on a sample piece of stainless steel to determine the optimal parameters for the desired results.

Step 3: Design Preparation

Create or import the design, text, or pattern into the laser engraving software.

Adjust the size, position, and orientation of the design as needed.

Step 4: Laser Engraving Process

Secure the stainless steel item in place within the engraving machine.

Initiate the engraving process according to the established settings and parameters.

Monitor the engraving progress to ensure accuracy and quality.

Step 5: Post-Engraving Care

Once the engraving is completed, remove the stainless steel item from the machine.

Clean the engraved area to remove any residue or debris from the surface.

Tips for Successful Engraving Stainless Steel

- Use high-quality stainless steel items for better engraving results.

- Adjust laser settings such as power, speed, and focus for optimal engraving depth and clarity.

- Conduct test runs on scrap pieces to fine-tune settings before engraving the final product.

- Ensure the stainless steel surface is properly cleaned and free from any oils or contaminants to achieve precise and clear engravings.

- Consider using specialized coatings or treatments to enhance the visibility and durability of the engraved markings.

FAQs About Stainless Steel Engraving

- Is Stainless Steel Good for Engraving?

Yes, stainless steel is an excellent material for engraving due to its durability, resistance to corrosion, and ability to hold detailed engravings. Its hardness and strength make it suitable for various engraving techniques, including laser engraving, rotary engraving, and chemical etching. The results are long-lasting, allowing for precise and permanent markings on stainless steel surfaces.

- Will Engraved Stainless Steel Rust?

Engraved stainless steel typically does not rust if the engraving process is performed correctly and the stainless steel's surface is properly maintained. The engraved area itself is unlikely to rust because the engraving process usually doesn't compromise the stainless steel's protective layer. However, if the surface surrounding the engraving gets damaged, exposing the underlying metal to moisture or corrosive elements, rust may occur in those areas.

- How Much Does It Cost to Laser Engrave Stainless Steel?

The cost of laser engraving stainless steel can vary based on several factors:

- Size and Complexity: Larger or more complex designs may require more time and resources, thus increasing the cost.

- Engraving Depth and Detail: Deeper or more intricate engravings might necessitate higher laser power and precision, affecting the cost.

- Quantity: Bulk orders may be eligible for discounts or lower costs per item.

- Laser Engraving Service Providers: Prices can differ among service providers based on their equipment, expertise, and location.

- Can I Engrave Stainless Steel at Home?

Yes! Engraving stainless steel at home is possible using various methods:

- Handheld Tools: Handheld rotary tools with diamond-tipped bits or specialized hand engraving tools can be used for simple designs.

- Chemical Etching Kits: Some kits allow etching on stainless steel by applying solutions using stencils for design.

- Engraving Machines: Small laser engravers or mini CNC machines designed for home use may work for stainless steel, but results can vary based on the machine's capabilities.

Conclusion

In conclusion, engraving stainless steel is a versatile and rewarding process that offers numerous creative possibilities. Whether for personalization, industrial applications, or artistic endeavors, mastering the art of engraving on stainless steel can unlock a world of opportunities.

While achieving professional-quality results may require practice, expertise, or specialized equipment, the ability to engrave stainless steel at home opens doors for DIY enthusiasts and small-scale projects. Embrace the process, enjoy the creative journey, and let stainless steel engraving be a medium through which your imagination takes form.