Laser cut wood has gained immense popularity due to its versatility and ability to create stunning, personalized pieces in recent years. The demand for laser cut wood creations has surged, making it a prominent choice for home decor, gifts, and even architectural elements.

This blog aims to explore the fascinating world of laser cut wood, its advantages, applications, suitable wood types, and providing practical tips for both beginners and enthusiasts. Join us on this journey to uncover the artistry and craftsmanship that laser cut wood brings to the forefront.

In this article:

Part 1: Advantages of Laser Cut Wood

Precision and Accuracy:

One of the main advantages of laser cutting wood is that it provides unparalleled precision and accuracy. The focused laser beam enables fine cuts, ensuring that even the most complex and detailed designs are executed with the highest precision, far beyond what is possible with traditional cutting methods.

Versatility in Design Possibilities:

Laser cutting wood offers a wide range of design possibilities, limited only by the creator's imagination. Whether it's intricate patterns, delicate filigree, or bold geometric shapes, laser cutting technology enables diverse and complex designs, producing everything from small decorative items to large architectural elements.

Reduced Material Wastage:

Laser cutting minimizes material waste compared to traditional cutting methods. Traditional cutting tools can remove more material than necessary, resulting in inefficiencies and increased costs. In comparison, laser cutting is a more economical option because it precisely targets the area to be cut, minimizing waste.

Eco-friendly Aspects of Laser Cutting:

Laser cutting wood adheres to environmentally friendly practices, making it an attractive option for environmentally conscious creators and consumers. Additionally, the process typically produces less dust and debris than traditional cutting methods, promoting a cleaner, greener workspace.

Part 2: What Types of Wood Are Suitable for Laser Cutting?

Hardwoods:

- Oak: Dense and strong with a classic grain pattern. Ideal for projects requiring durability and a timeless aesthetic.

- Walnut: Dark and rich tones with fine grain for intricate details. Adds elegance to laser cut wood projects.

Plywood:

- Baltic Birch: Multi-ply construction for consistency. Smooth surface for precise laser cutting, versatile in applications.

- MDF (Medium-Density Fiberboard): Even surface for intricate designs. Suitable for various laser cut wood projects.

Exotic Woods:

- Bamboo: Sustainable and eco-friendly. Light color and unique grain for modern designs.

- Cherry Wood: Warm tones with fine grain. Timeless beauty for laser cut wood creations.

Part 3: How to Laser Cut Wood at Home?

Laser cutting wood at home can be a rewarding and creative endeavor. Here are essential tips to ensure a successful and enjoyable experience:

Step 1 - Machine and Material Preparation:

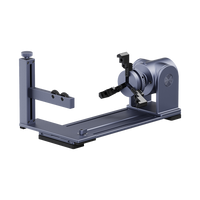

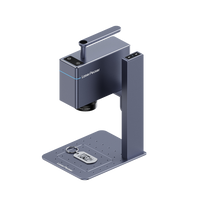

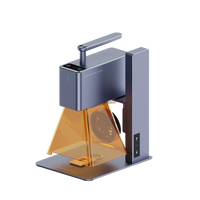

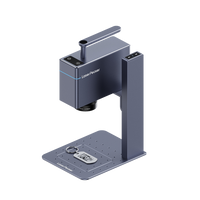

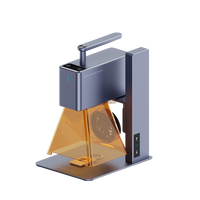

Select a kind of laser cutting machine that can laser cut wood even at home. We recommended LaserPecker LX1 Compact and Multifunctional Laser Cutter.

Choose wood with minimal knots or imperfections. Ensure the wood is flat and secure it properly on the laser bed to prevent movement during cutting.

Step 2 - Choosing the Right Settings:

Adjust laser power, speed, and frequency based on the type and thickness of the wood. Conduct test cuts on scrap pieces to fine-tune settings before starting the main project. Consult the laser cutter's manual for recommended laser settings.

Step 3 - Design Considerations:

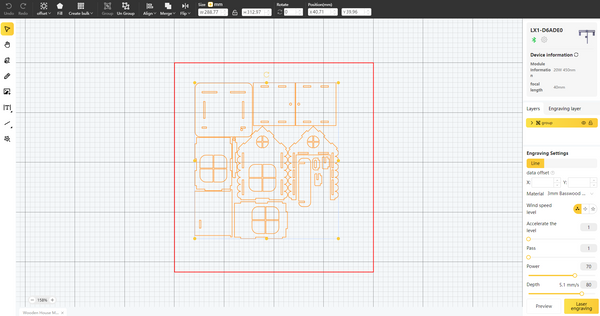

Use LaserPecker Design Space software to create designs. Convert text and graphics into vector paths for precise cutting. Consider the kerf (width of the laser beam) when designing interlocking pieces.

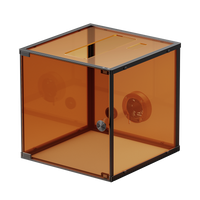

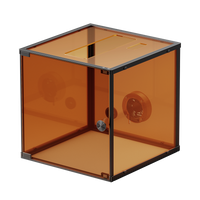

Step 4 - Ventilation and Safety:

Ensure proper ventilation to remove smoke and fumes generated during the cutting process. Wear appropriate personal protective equipment, including safety glasses and respiratory protection. Keep a fire extinguisher nearby and follow all safety guidelines provided by the laser cutter manufacturer.

Step 5 - Calibration and Alignment:

Regularly calibrate and align the laser cutter to maintain accuracy. Check the focal length to ensure the laser is focused correctly on the wood surface.

Step 6 - Test on Material:

Before starting the main project, conduct test cuts on wood of the same type to verify settings and design integrity.

Step 7 - Post-Cutting Steps:

Allow the cut wood to cool before handling. Remove any remaining residue or char using a soft brush or compressed air. Sand the edges for a smooth finish if necessary.

Then, follow the below steps to finish this little cute laser cutting wooden house. For more info of this project, please visit our LaserPecker CraftZone.

Step 8 - Maintenance:

Clean the laser cutter's lens and mirrors regularly for optimal performance. Lubricate moving parts as per the manufacturer's recommendations.

Part 4: Applications of Laser Cut Wood

Home Decor:

Laser cut wood has become a staple in the realm of home decor, offering a unique blend of functionality and artistic expression. From intricate wall art and stylish furniture pieces to ornate clocks and decorative ornaments, laser cut wood brings a touch of sophistication and personalized charm to homes. Visit LaserPecker CraftZone for the steps for laser cutting wood home decor project below.

Personalized Gifts:

The ability to engrave and customize makes laser cut wood an ideal choice for crafting personalized gifts. Whether it's engraving names, dates, or special messages, laser cut wood allows for the creation of unique keepsakes and memorable tokens that go beyond the ordinary. Visit LaserPecker CraftZone for the steps for laser cutting wood personalized gift project below.

Architectural Elements:

Laser cut wood is increasingly finding its place in architectural applications, adding a touch of uniqueness to buildings and spaces. The versatility of laser cut wood extends beyond the confines of smaller projects, making it a viable option for architects and designers seeking innovative solutions.

Part 5: Frequently Asked Questions about Laser Cut Wood

1. Can I use any laser cutter for wood?

Different laser cutters have varying power and capabilities. Ensure that your laser cutter is suitable for wood cutting and meets the specifications for the thickness and type of wood you plan to use.

2. How do I avoid burning or discoloration on the wood surface?

Adjust the laser settings to reduce power and increase speed. Testing on scrap wood helps find the right balance between cutting and avoiding excessive burning.

3. Can I use laser cut wood for outdoor projects?

Sealing laser cut wood with an outdoor-grade finish can enhance its durability. However, prolonged exposure to the elements may still impact the wood over time.

4. Is laser cut wood environmentally friendly?

Laser cutting minimizes material wastage, and using sustainably sourced wood makes it an eco-friendly choice. Consider the environmental impact of the wood type and any finishes used.

5. Can I cut thicker wood with a laser cutter?

Laser cutters have limitations on the thickness they can effectively cut. Check your laser cutter's specifications and consider multiple passes for thicker materials.