Engraving a bracelet can be a creative and personalized way to add a unique touch to your accessories. Various methods and machines are available to achieve this, each offering distinct features and capabilities.

Whether you opt for laser engraving for precise detailing, rotary engraving for versatility, CNC engraving for programmable precision, or handheld tools for smaller projects, the choice depends on your specific needs and preferences. In this guide, we'll explore the guide on how to engrave a bracelet.

In this article:

Part 1: What Machine Do I Need to Engrave A Bracelet?

To engrave a bracelet, you'll typically need a specific type of machine called an engraving machine or engraver. There are different types of engraving machines available, and the choice depends on the materials you plan to engrave and the level of detail you want. Here are some common types of engraving machines:

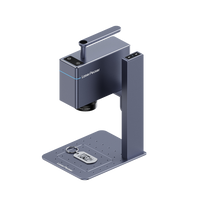

1. Laser Engraving Machine:

Pros: Precise and detailed engraving, suitable for a variety of materials including metal, wood, plastic, glass, and more.

Cons: Generally more expensive compared to other types of engravers.

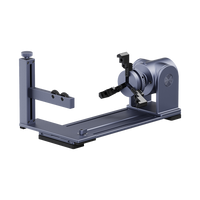

2. Rotary Engraving Machine:

Pros: Versatile for engraving on metal, plastic, wood, and other materials. Can handle both flat and curved surfaces.

Cons: May not be as precise as laser engraving for intricate designs.

3. CNC Engraving Machine:

Pros: Computer Numerical Control (CNC) engravers are versatile and can handle various materials. They provide precision and can be programmed for intricate designs.

Cons: Can be more complex to operate and may require some technical knowledge.

4. Handheld Engraving Tools:

Pros: Portable and suitable for smaller projects. Can be less expensive than dedicated engraving machines.

Cons: May not be as precise as machine engraving.

When choosing an engraving machine, consider the following factors:

- Material Compatibility: Ensure that the machine can engrave on the material of your bracelet (e.g., metal, leather, plastic).

- Detail and Precision: Consider the level of detail you need for your engraving.

- Ease of Use: Choose a machine that matches your skill level and technical expertise.

- Budget: Engraving machines vary in price, so consider your budget when making a selection.

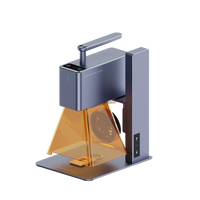

Part 2: How to Laser Engrave A Bracelet?

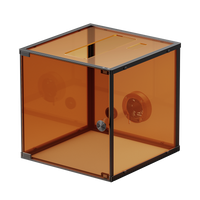

Laser engraving a bracelet involves using a laser engraving machine to mark or cut a design onto the surface of the bracelet. Here is a general step-by-step guide on how to laser engrave a bracelet:

Step 1. Choose the Laser Engraving Machine:

Select a laser engraving machine suitable for your bracelet material. Ensure the machine is equipped with the right power and settings for your specific project.

Step 2. Prepare the Design:

Create or obtain the design you want to engrave on the bracelet. This can be a logo, text, pattern, or any other artwork.

Step 3. Prepare the Bracelet:

Clean the surface of the bracelet to remove any dust or debris. Ensure it is flat and positioned securely within the engraving area.

Step 4. Calibrate the Laser Engraving Machine:

Calibrate the laser engraving machine according to the specifications for the material you're working with. This may involve adjusting the focus, power, and speed settings.

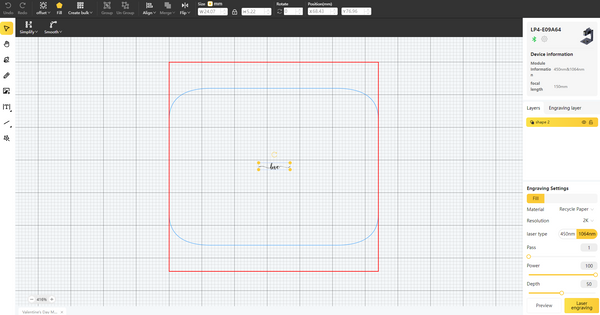

Step 5. Load the Design into the Software:

Use the software provided with the laser engraving machine to load your design. Arrange and scale the design to fit the bracelet.

Step 6. Preview and Adjust Settings:

Preview the design in the software to ensure it appears as intended. Adjust settings such as power, speed, and resolution as needed.

Step 7. Secure the Bracelet in the Machine:

Place the bracelet in the engraving machine's work area and secure it in place to prevent movement during engraving.

Step 8. Run the Engraving Job:

Start the laser engraving process using the software. The laser will follow the specified design and engrave it onto the bracelet. Monitor the process to ensure the quality of the engraving.

Step 9. Clean the Engraved Bracelet:

Once the engraving is complete, carefully remove the bracelet from the machine. Clean off any residue or debris from the engraving process using a soft brush or cloth.

Step 10. Inspect and Finish:

Inspect the engraved bracelet to ensure the quality meets your expectations. Depending on the material, you may want to apply a protective coating or finish to enhance durability and appearance.

If you want to learn more about laser engraved bracelet projects, visit our LaserPecker CraftZone!

Conclusion

Engraving a bracelet opens up a world of possibilities for expressing individuality and creating meaningful pieces of jewelry. The choice of engraving method and machine depends on factors such as material, design complexity, and personal skill level. Laser engraving provides precision on various materials, while tools like the Cricut Maker offer versatility through their Engraving and Debossing Tips.

Whichever method you choose, following proper guidelines, practicing on scrap materials, and paying attention to detail will ensure a successful and aesthetically pleasing result. Whether you're crafting a special gift or adding a personal touch to your own collection, the art of bracelet engraving allows for endless creativity and self-expression.